In today’s industrial manufacturing world, precision, performance, and scalability define success. Investment casting has developed into one of the most critical technologies for crafting complex metal parts. This adaptable method makes it possible to design elaborate shapes, fine details, and superior surfaces, which traditional machining, forging, or other methods fail to accomplish. This is why the aerospace, automotive, and marine industries need to choose the right casting partner. Bessercast has established itself as an industry leader, owing to its advanced technologies, craftsmanship, and complete manufacturing capabilities. Investing with an experienced precision investment casting manufacturer and complete-service foundry, like Bessercast, helps improve a business streamlining production and lowering costs while ensuring consistent and high-quality components for highly demanding applications. This article describes the most crucial advantages of investment casting factories for metal complex components, especially B2B companies, for advanced casting techniques, integrated services, and sustainable manufacturing.

Accuracy and Flexibility of Design

Investment casting differs from all other casting types because of the accuracy and the intricacies of the designs that can be achieved using wax patterns and ceramic molds. The production tolerances can be CT4 – CT6 and the surface finishes can be as smooth as 3.2Ra. Investment casting achieves accuracy that enables the production of designs that would have been achieved through several machining steps.

Bessercast’s silica sol casting technology achieves this near net shape production with less material wastage and post-processing. This efficiency is of great importance to industries like turbine engines, pumps and automotive components that require great precision in their performance.

Investment casting also has the ability to support highly versatile material choices like stainless steel, carbon steels, nickel alloys, and duplex steels, making it a great option for custom jobs. Investment casting has the ability to consistently deliver great results whether it is for the lightweight components that are often needed in the aerospace industries or for the corrosion resistant components that are needed in the marine industries.

Excellent Finish Quality and Structural Performance

Surface finish and structural integrity are essential parameters for any high-performance metal piece. Traditional means of manufacturing take a long time during machining and polishing processes to obtain a finished surface. On the other hand, investment casting obtains a finish and presents a better surface and fewer surface mistakes.

Bessercast has invested in advanced casting simulation software and perfected its shell making to ensure a consistent and uninterrupted flow of metal of uniform and surface. This makes a component with attractive surface finish and solid mechanical and enduring value.

The high surface finish of the component results in reduced friction and enhanced performance in rather more severe conditions This surface finish is of high value to components of precision purpose in valve systems and other high pressure applications.

By collaborating with a precision investment casting manufacturer and materials expert, companies obtain components that need minimal finishing allowance, thereby curtailing lead-times and unit costs.

Range of Materials and Application Freedom

Partnering with a full-service investment casting factory like Bessercast has benefits. One of the many is the availability of a variety of materials. Different alloys are carefully chosen and tailored to suit the mechanical and environmental needs of each industry.

Bessercast can produce more than 200 types of alloys with the following specializations:

- Stainless Steels of 300 and 400 series used commonly for food, construction, and marine for corrosion resistant elements.

- Carbon and Low-Alloy Steels used on elements that require durable and high-wear resistant components.

- Duplex Stainless Steels used on areas that require an equilibrium between corrosion resistant and mechanical strength.

- Nickel Alloys used for high temperature aerospace and power generation activities.

- Tool Steels used for the construction of dies, molds, and other industrial types of activities that are heavy-duty.

B2B clients are able to have the entire variety of materials portfolio with one supplier for different products which streamlines the procurement processes and assures the customer of quality. This capability also ensures that the client is able to receive specialized investment casting projects because of the custom alloys. Not all investment casting factories can provide these specialized alloys.

Integrated Manufacturing Capabilities.

Large industrial buyers require suppliers to provide all services from one place. Bessercast is more than just a casting provider; it is a complete manufacturing partner with all the casting services. These include:

- Heat Treatment improves on the hardness, toughness, and wear resistance of the components for different applications.

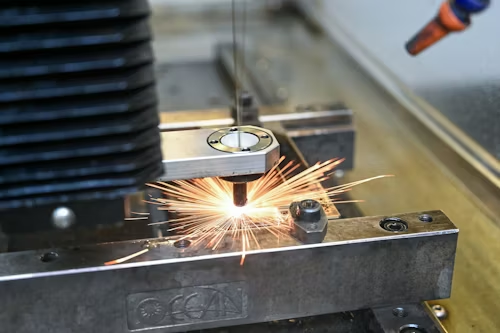

- CNC Machining is used for different complex components to meet the desired precise tolerances.

- Surface finishing combines all activities of sanding, polishing, and coating for enhanced performance and appearance.

- Assembly Services: Providing completed, ready-to-install parts immediately to the production line.

This integration also achieves a significant reduction to lead times, is less expensive to ship, and guarantees all parts produced are within the customer’s requirement. It also improves the ease of managing the supply chain, because the company can do the casting, machining and assembly of parts all under one contract.

When working with a precision investment casting manufacturer and integrated service provider, B2B Companies can improve the efficiency of production and concentrate on value-added activities instead of managing many suppliers.

Quality Assurance and Global Standards

Wherever there is a need for quality assurance, an industry’s safety and performance depends on it. Bessercast has rigorous quality controls in all processes of production in order to comply with the customer’s requirements and international standards.

The factory’s QC teams perform the following checks:

- Dimensional measurement using coordinate measuring machines (CMM).

- Non-destructive testing (NDT) like X-ray, ultrasonic, and magnetic particle inspection.

- Mechanical testing for hardness, tensile strength and elongation.

- Metallurgical testing for microstructure and alloy consistency.

Bessercast also practices 5S workshop management to further sustain the efficiency and orderliness of processes. The collaboration of automation, experienced personnel, and comprehensive quality processes in place ensure that all castings are produced within the desired tolerances and performance levels.

Investing in construction according to quality guidelines allows B2B customers to have confidence that their pieces will work seamlessly in mission critical use and will function in planes, construction machinery, or energy equipment.

Cost Efficiency and Supply Chain Optimization

Investment casting is cheaper than most traditional manufacturing processes and offers even more ideal cost functionality. Because it offers to create near-net shape parts, it allows for a reduction in material waste and machining time. **Bessercast* increases these efficiencies even more due to their smart Design Optimization, Automated Shell Manufacturing, and line mass production.

Some other factors allowing for even more cost efficiency include shorter lead time, reduced machining and welding, and lower transport and communication costs due to a one-stop production offering.

For buyers in B2B, especially for those that manage large scale operations, these efficiencies allow for a distracted and predictable pricing system, faster time to market, and a better profit margin.

Conclusion

Choosing an investment casting factory is a choice that is, in some ways, strategic due to its impact on product quality, production efficiency, and long term maintenance of a competitive position in the market. Bessercast is a perfect example of the utilization of complex technology and material capability in seamless and integrated manufacturing systems.

Working with a precision investment casting manufacturer and full-service provider like Bessercast gives B2B companies unmatched precision and quality consistency at scalable solutions perfectly fitted to their industry needs. Investment casting continues to innovate and increase efficiency and sustainable practices for global markets; aerospace, construction, automotive, and industrial equipment.

As industries strive for performance and precision, Bessercast continues to redefine excellence and assist companies across the world with their engineering needs in a timely, cost-effective, and reliable manner.